Power Discretes, Hybrids, & Modules

Two Terminal Power Packages

- Button Tab

- Sedpack and Centertap Sedpack

- Surface Mount Packages for Rectifiers, Schottkys, Zeners and TVS

Three Terminal Power Packages

- Cerpack

- SMD Packages for FETs, IGBTs, Bipolar NPNs and PNPs, Thyristors

Power Hybrids

- Full in-house design and prototype capability

- Package / lead modifications

- Address additional requirements / modifications such as built-in Zener diode protection, gate resistor, built-in isolated / non-isolated gate drivers and anti-parallel diode for faster switching

- Production of small to large volumes of different product-mix

- Customized functional testing

- Combination of hybrid and SMT

- Substrate: 96% alumina, aluminum nitride, Al2O3 DBC, ALN DBC, BeO DBC

- Die selection / matching for optimal performance over the full operating temperature range

- Die bonding with a variety of eutectic or high temperature soft solders or epoxies

- Ultrasonic Al wire bonding from 0.001" to 0.20" dia.

- Hermetic sealing

- Gross and fine leak verification

- Bond pull and die shear strength testing

- Screening and processing per MIL-PRF-38534

- Three phase bridge

- Half bridge switch

- Full bridge switch

- Boost converter

- Buck converter

- Double forward converter

- Thrust vector controls

Power Module Advantages

- Improved Performance - discrete components are tested at full current / power ratings and can be selected for matched performance prior to PM assembly

- Improved Reliability - uses prescreened & qualified components and thermally matched materials to maximize power evacuation while minimizing thermal stress

- Higher Working Currents and Lower Conduction Losses– replaces wire bonds with heavy gauge, high current handling heatsunk copper traces

- Weight Reduction – uses lightweight materials

- Simplified Next Level Assembly – terminations optimally located to interface with the system

- Any Size or Shape – takes full advantage of available system real estate, including 3D capability

- Any Terminal Type– high power threaded, soldered male/female turrets, flex cable, power bar, etc; mix & match different control and power connections

- Repairable / Reworkable

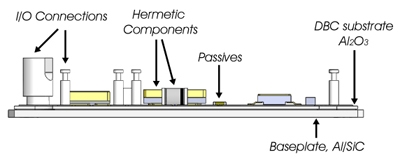

Performance / Features

- High thermal conductivity

- Layout optimized for circuitry and I/O

- Includes passive components such as:

- Thermistors or current sense resistors

- Capacitors

- Inductors

- Thermal stress minimization via CTE matched materials

- Application specific solution

- Simplifies procurement with single item